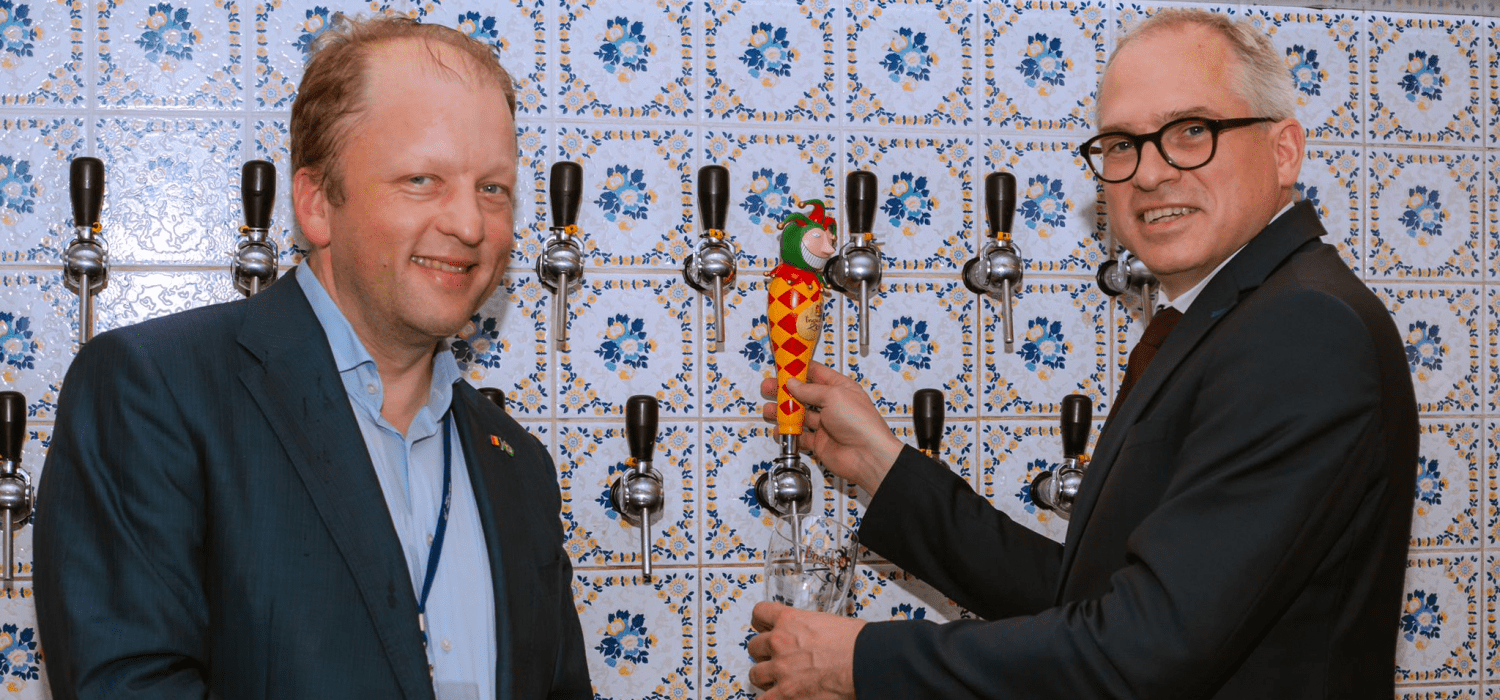

Construction of the new Halve Maan bottling plant in Bruges started

Brewery De Halve Maan has started the construction of a new bottling plant for the further growth and foreign expansion. The first spade was pulled on Friday, November 29. The current bottling plant has literally burst out of its seams after various expansions: additional tanks, installations or warehouses were added or built almost every year. The brewery wants to make the new building a real "landmark" with the necessary appearance in Bruges.

The plans include new filling lines that are 3 times the size of the current ones. The new bottling line will process 24000 bottles per hour and the barrel line up to 180 barrels per hour. Additional tanks, filtration, warehouses, hot rooms and logistical storage will also be built to accommodate the extra capacity. In collaboration with its partners, the brewery has developed a number of new technologies that should make the new production apparatus even more efficient, performant and flexible. The investment is thus more than a mere expansion of the brewery's capacity. These innovations should drastically reduce the brewery's ecological footprint and it should provide the brewery with even better facilities to successfully undertake its international expansion into various countries around the world. Today, the brewery exports 45% of its volume to more than 40 different countries.

"Innovation helps productivity and competitiveness and that is what we must strive for." says Vice Minister President Hilde Crevits, responsible for Innovation and Economy.

The design of the building combines various functions: in addition to production with process areas and filling lines, there is also room for warehousing, logistics and offices. All this is combined with attention to ecology and a good use of space. The choice was made for an energy-efficient building with a green roof and an underground car park. It was a conscious choice for the brewery not to carve out a new open space for the expansion but rather to work with a smart conversion of existing industrial land.